[For Overseas Automotive Manufacturer] Vehicle Semi-Anechoic Chamber

Project Case Study | Vehicle Semi-Anechoic Chamber A vehicle semi-anechoic chamber was delivered for an overse...

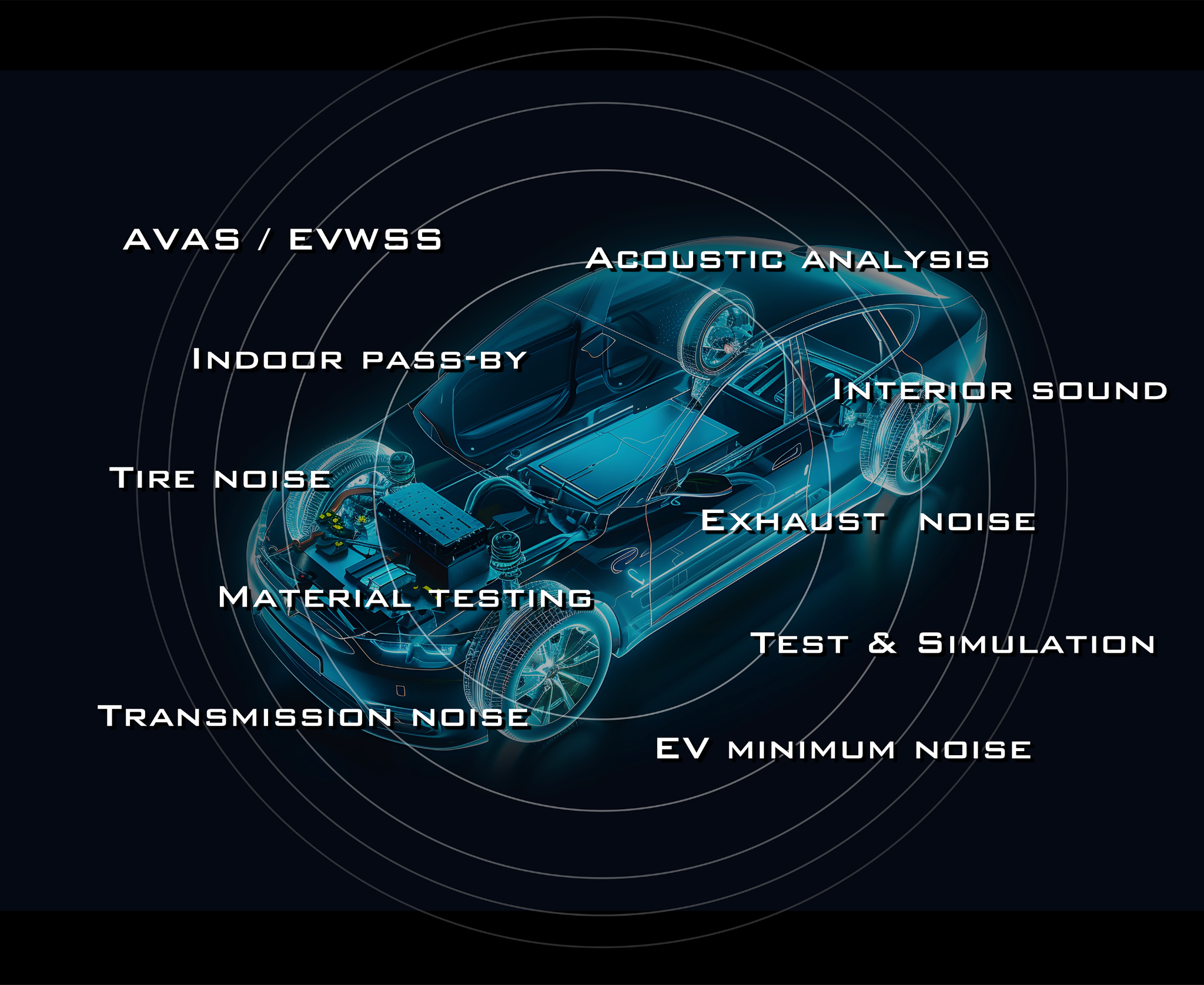

In order to conduct the different types of Vehicle NVH Testing, the development of VSAC and setting of the environmental requirements for performing measurements are important tasks for automotive manufacturers and manufacturers of automotive parts and components as well.

We propose: Acoustic measuring instruments + Semi-anechoic chambers.

ISO 3741

ISO 3744

ISO 3745

ISO 362-1, -2, -3

ISO 13325

ISO 26101-1

ISO 20908

ISO 8253-2

ISO 11201

ISO 15186-1

We propose: ISO standard semi-anechoic chambers.

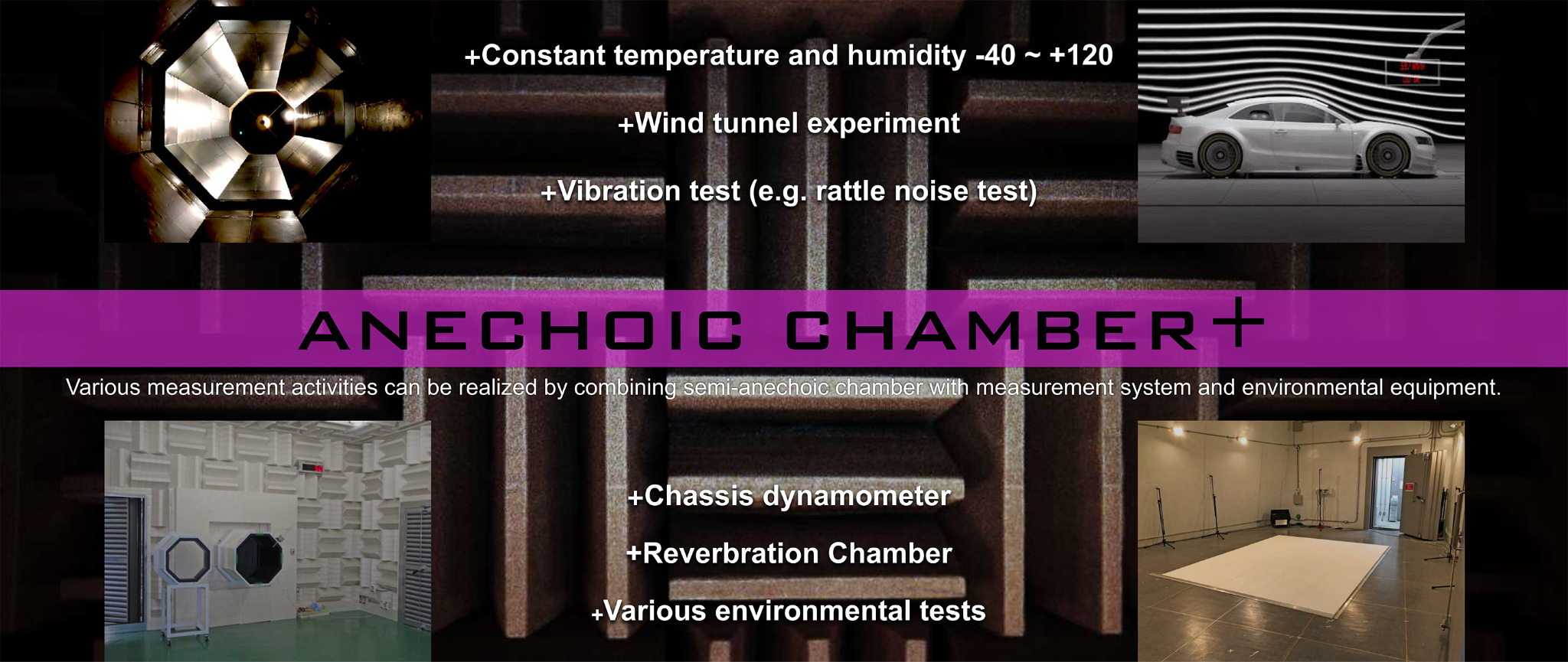

We propose: Semi-anechoic chamber + ancillary equipment.

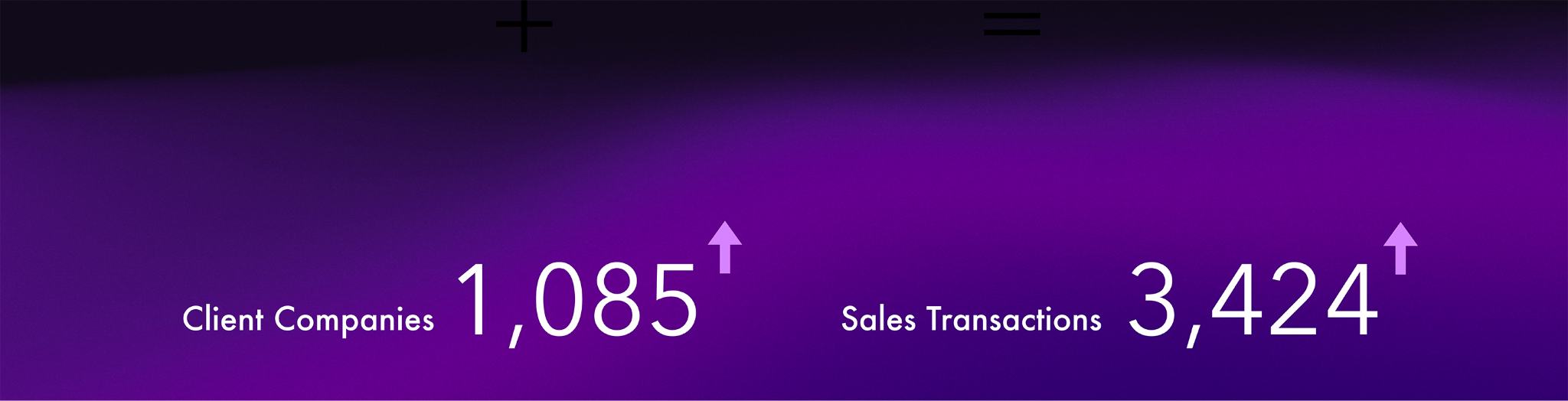

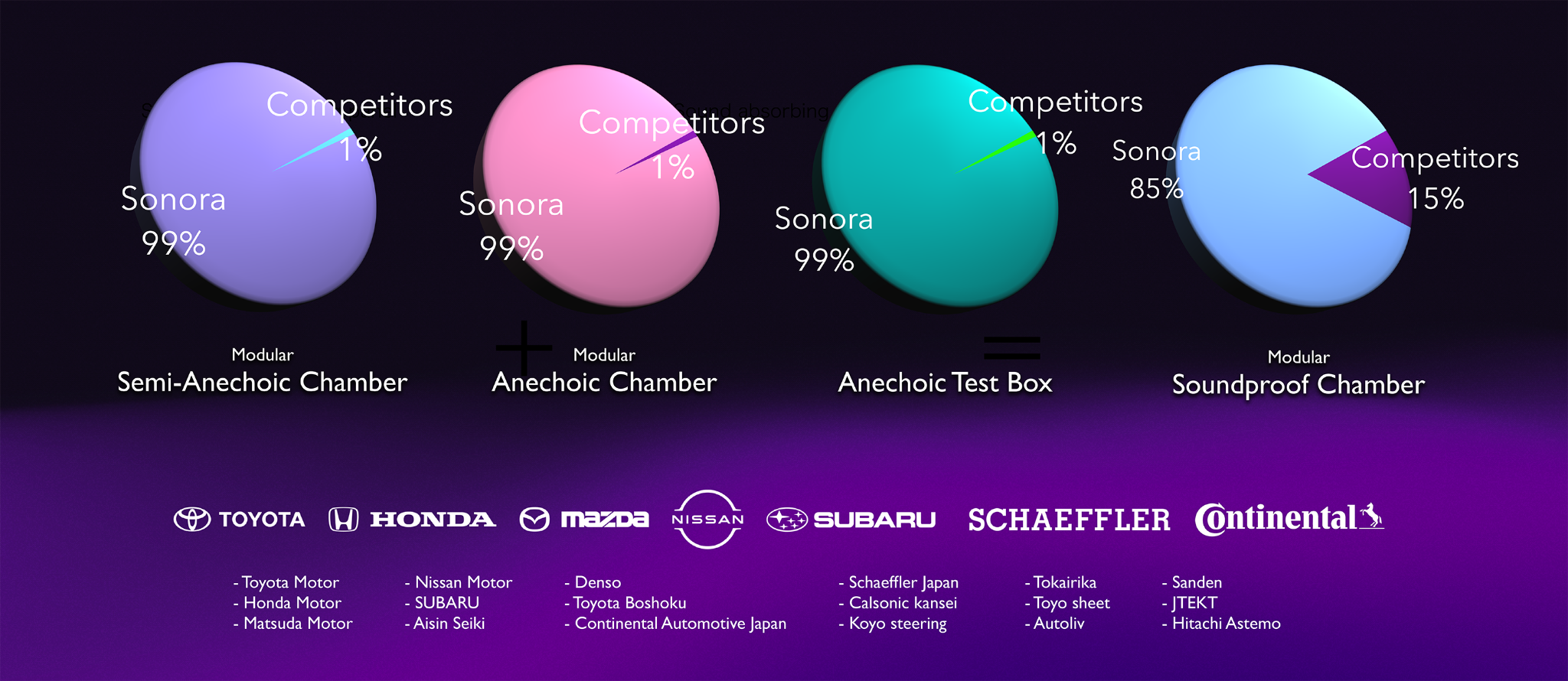

Since our foundation in 2003, Sonora Technology has been receiving a large number of orders from various customers, mainly from automobile manufacturers and home appliance manufacturers. We have established ourselves as a niche top manufacturer of chambers and boxes for acoustic measurement in Japan. (We have the no.1 domestic sales share of the modular anechoic chambers, modular semi-anechoic chambers, and anechoic boxes. *according to our research) As of 2023, we have managed to deal with 1,085 companies with 3,424 projects.

Sonora Technology has been satisfying customers’ requirements. We have been overcoming various challenges with a strong mind-set to keep up with increasingly dynamic needs required by major companies.

“Sonora Technology is more than just a manufacturer.”

When major companies order our anechoic chamber, it is not enough for us only to deliver the product according to their required specifications.

They have many requirements, for example, “we want to conduct combined testing in a constant temperature and humidity environment”, “need a cleanroom compatible”, “remove the steps”, “need an automatic door”, “be relocatable” …etc. 65% of our projects are custom-made in addition to our standard products. Such experiences enabled us to build up our own know-how.

The more demands are required by customers in terms of noise reduction and vibration damping, the more improvement of specifications will be required according to them. The technology of acoustic control has not been established yet in academia. It is not possible to keep up with the changing of the times only using the existing technology.

Sonora Technology opened our own factory and research and development facilities in 2009, enabling us to manufacture various products with our developed unique technology. We keep continually moving forward in research and development on a daily basis.

We are currently unknown outside of Japan. However, manufacturers of acoustic anechoic chambers in the world are not our competitors. We have been overcoming challenges in order to satisfy the strict Japanese standards up to now. In 2024, our overseas sales are finally starting up all across the world.

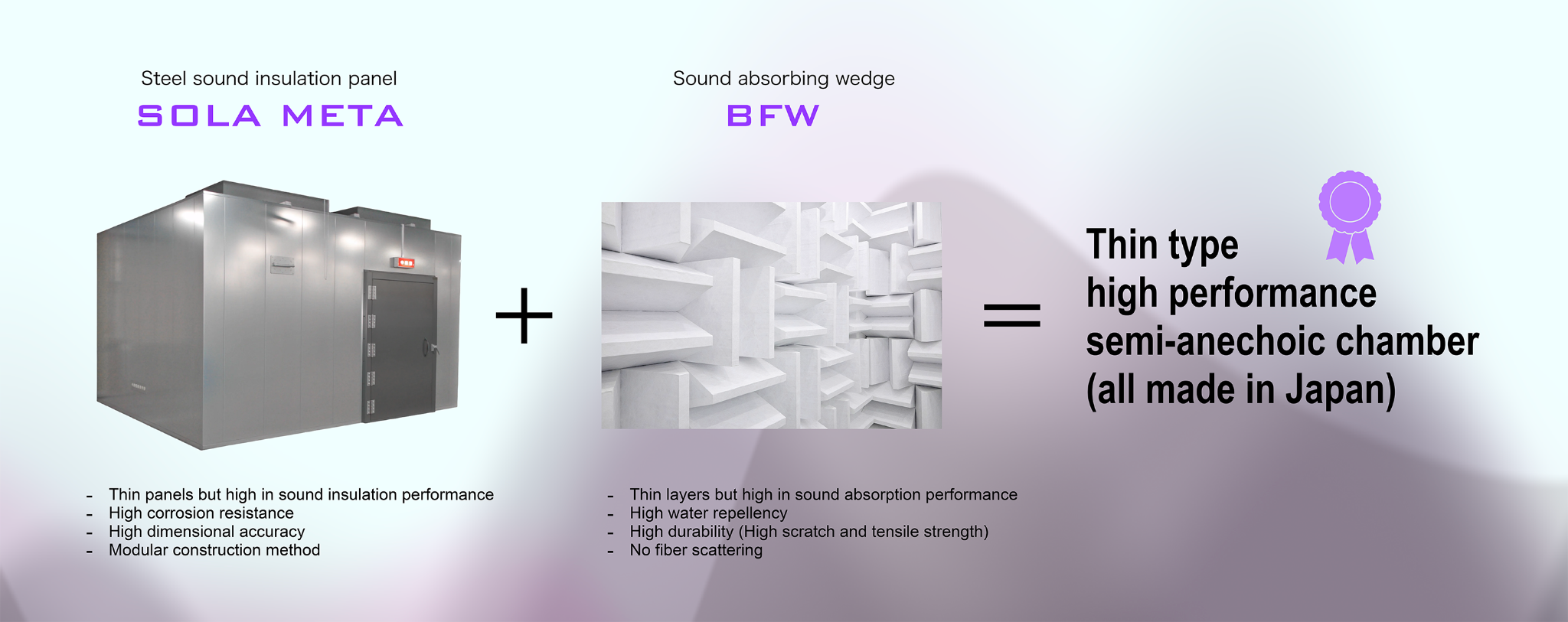

Sound insulation layer: composed of in-house developed steel sound insulation panels.

Only 40mm to 150mm thickness depending on the required sound insulating value.

Feasible significant space savings, compared to the concrete layer as conventional construction methods.

Sound absorbing layer: Composed of in-house developed sound absorbing wedges.

High sound absorption despite its low profile.

Selected according to the required sound absorption performance.

60% to 80% less thickness compared to the conventional products. Space-saving design.

Modular frames and panels enable dismantling and relocating.

Saving costs when changing layouts.

Excellent dimensional accuracy due to prefabrication in factories.

Sonora guarantees sound insulating value and sound absorption performance.

High performance despite low profile.

Our anechoic chamber is second to none.

All component parts are manufactured in factories in Japan.

Ensure premium quality with state-of-the-art equipment. “MADE IN JAPAN.”

Workflow automation in production processes.

Competitive price thanks to space-saving design avoiding unnecessary costs.

Less expensive than the offered prices by other companies in terms of the same conditions.

Since 2003, Sonora Technology has achieved to deal with 1,024 companies, mainly among major Japanese companies, and concluded with 3,229 deals for around 20 years.

Sonora Technology has been satisfying clients’ requirements as a leading manufacturer of the ready-to-assemble anechoic chamber in the Japanese market. Since our foundation, we have been overcoming various challenges with a strong mind-set. Thanks to that, now we possess the right expertise, unique technologies and various kinds of strengths. We are confident to make effective proposals.

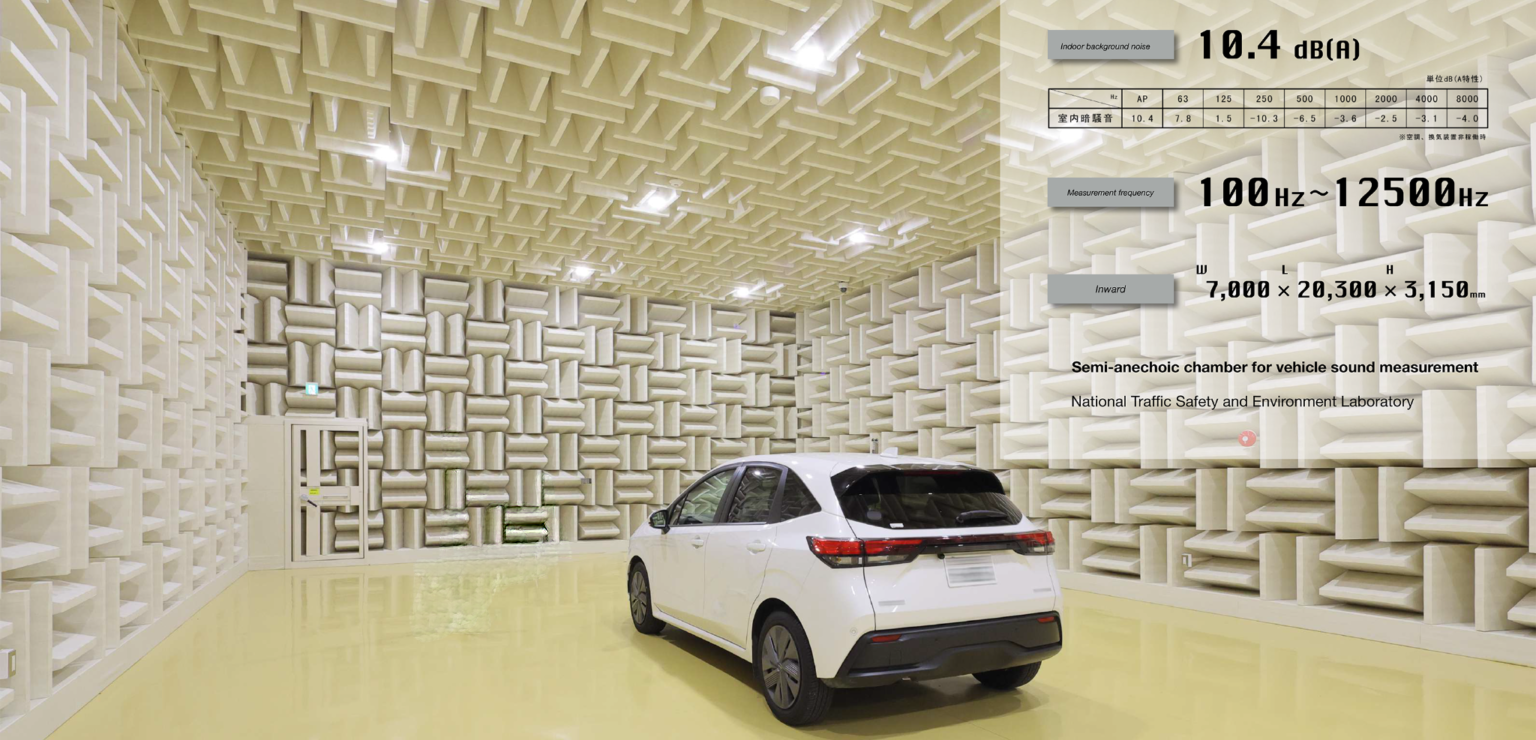

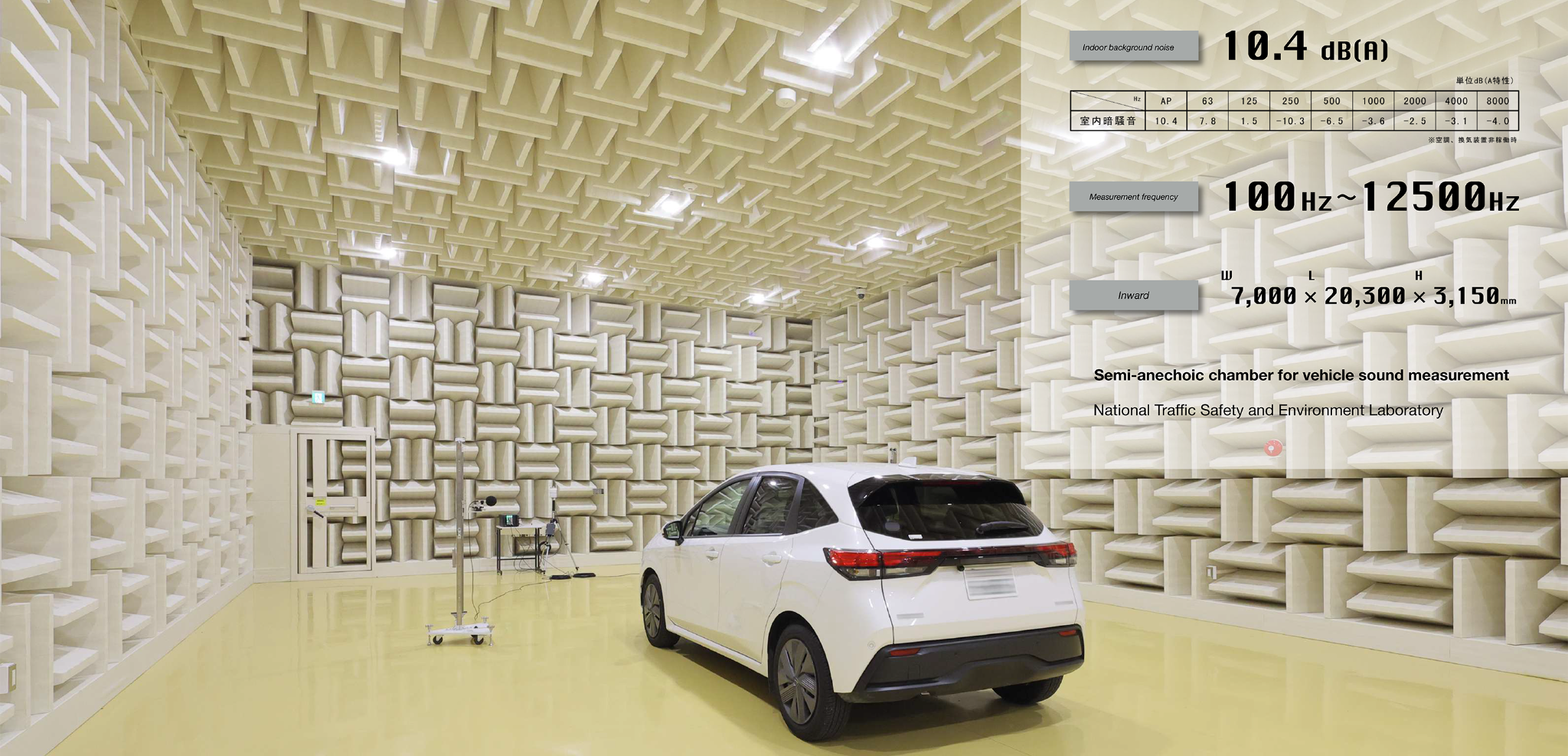

Semi-anechoic chamber for indoor pass-by testing for automotive manufacturers.

Large semi-anechoic chambers are also designed using the “independent construction method”, not to be connected with walls and ceilings of the building.

National traffic safety and environment laboratory.

Semi-anechoic chamber for conducting commissioned acoustic tests on vehicles at a public institution in Japan.

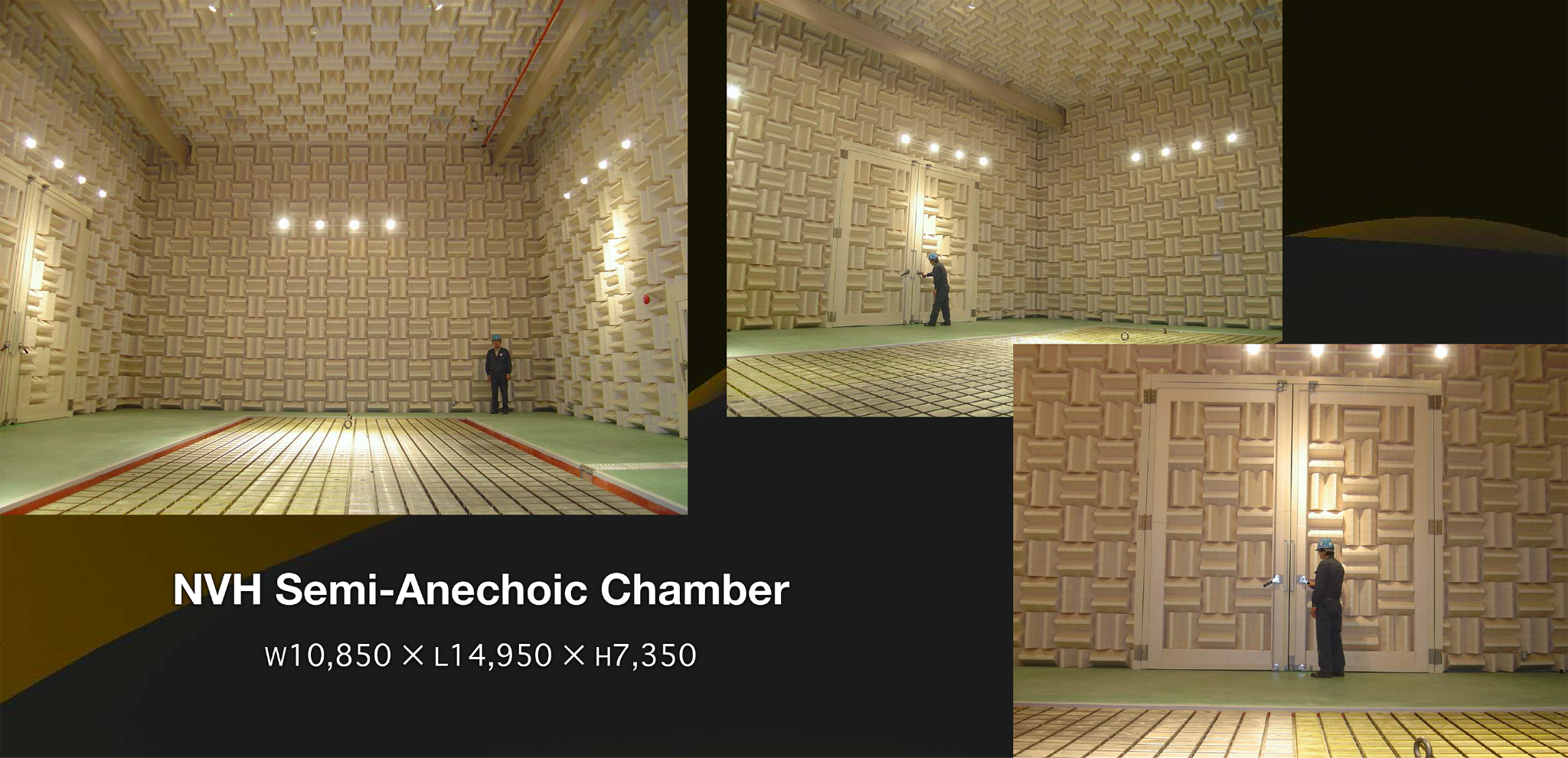

Automotive parts manufacturer.

The bottom part of the loading/unloading door has a step-free “flat sill structure.”

Chassis dynamo manufacturer.

Semi-Anechoic chamber for acoustic measurement and analysis on large vehicles such as trucks.

We are your partner.

Just leave the construction of VSAC to Sonora Technology.

Our practical knowledge, skills and expertise will surely be at your service.