Why is the tip of the acoustic wedge cut?

12/04/2024

MFAC / MSAC

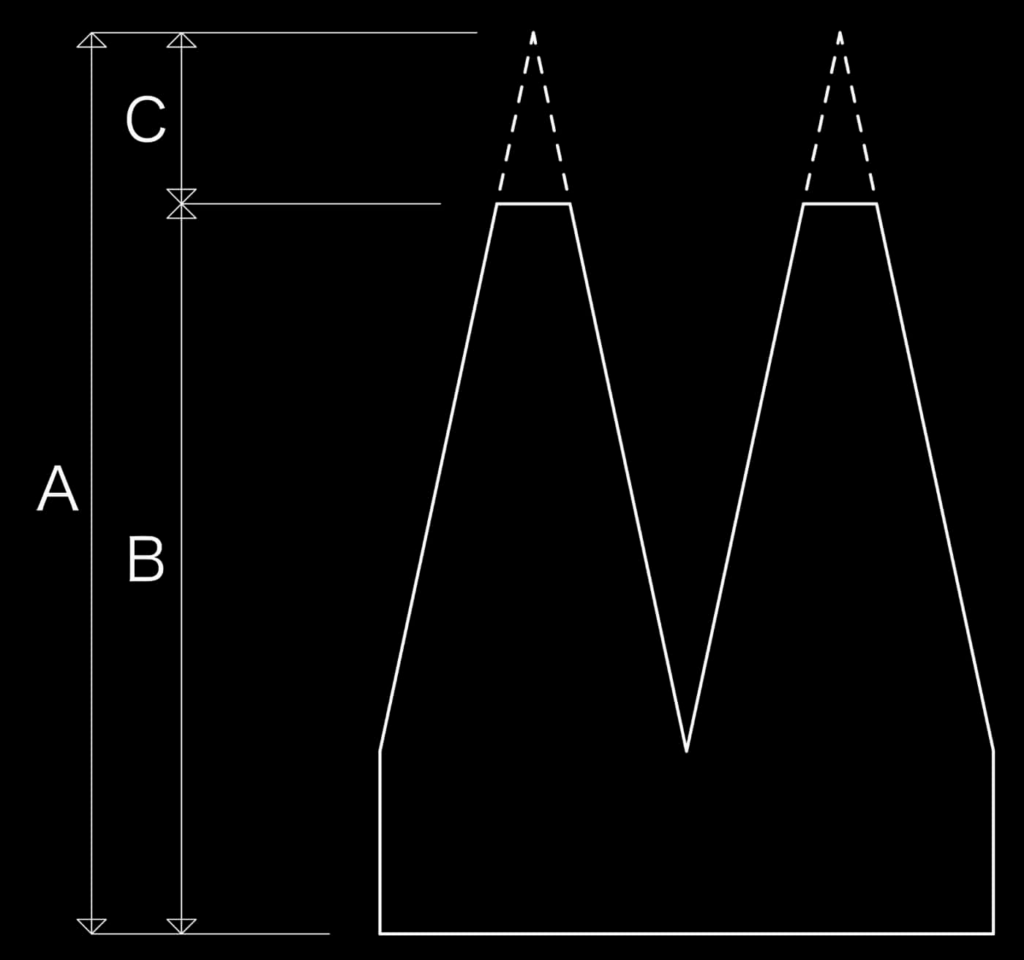

Acoustic wedges typically have a cut tip rather than a pointed one, as shown in the photo. I would like to explain the reason for this.

Originally, acoustic wedges were supposed to have dimension. A as shown in the diagram above. However, when checking the wedges from various anechoic chamber manufacturers, it is common to find that the tip is cut to dimension C, typically ending at dimension B.

In the traditional design method for acoustic wedges, a thickness of λ/4 (one-quarter of the wavelength of the target frequency) was required. Based on this reasoning, when comparing A and B, it can be said that A has better sound absorption performance.

However, in the past, K institute published findings showing that the sound absorption performance remains almost unchanged even without a pointed tip. As a result, wedges with cut tips have become the standard.

In other words, although the thickness of the wedge is B, it can still provide sound absorption performance equivalent to that of thickness A.

The presence of the C section reduces the effective space in the anechoic chamber and presents issues such as weaker strength, fragility, and a higher likelihood of deformation or damage from contact. Therefore, there has been ongoing discussion about eliminating the C section, and it is likely that the experiments conducted by K institute were carried out in this context.

Additionally, traditional acoustic wedges were made with wire frames, so if they had a pointed tip. It would be hard and sharp, posing a safety hazard.

Furthermore, if the C section is present, resonance could occur depending on the frequency range, and in practice, the volume is so small that any apparent effect would have been negligible.

Based on the above considerations, it was determined that acoustic wedges without a pointed tip are more practical, which is why the current trapezoidal wedge design has become standard. However, it is expected that the shape of the wedge will continue to be optimized by various manufacturers and researchers in the future.