Difference Between Traditional Reverberation Rooms and SONORA’s Steel Reverberation Rooms

04/18/2025

Others

Characteristics of Traditional Reverberation Rooms

Traditional reverberation rooms are typically constructed using concrete or masonry walls, floors, and ceilings, with surfaces designed to maximize sound reflection. Their main characteristics include:

| Heavyweight Structures | Extremely heavy construction (e.g., over 300mm thick concrete walls) to achieve high sound insulation based on the mass law. |

| High Reflectivity | Minimal use of sound-absorbing materials to maintain a long reverberation time. |

| Long Construction Period and High Cost | Long construction, high costs. |

| Permanent Structures | Once installed, relocation is not possible. |

This traditional approach has been common for rooms built according to standards like ISO 3741 (Precision Method for Measuring Sound Power in Reverberation Rooms).

Characteristics of SONORA’s Steel Reverberation Rooms

SONORA’s steel reverberation rooms represent a revolutionary design, distinctly different from traditional types. Their features include:

| Lightweight and Modular Structure | By using high-strength steel panel units, SONORA achieves a significant reduction in weight while maintaining durability. Thanks to modular panel construction, quick installation and easy relocation are possible. |

| High Sound Insulation Performance | By incorporating a unique damping structure (e.g., damping layers and reinforcements within the panels), SONORA enhances sound insulation not just through mass but also by damping vibrations. |

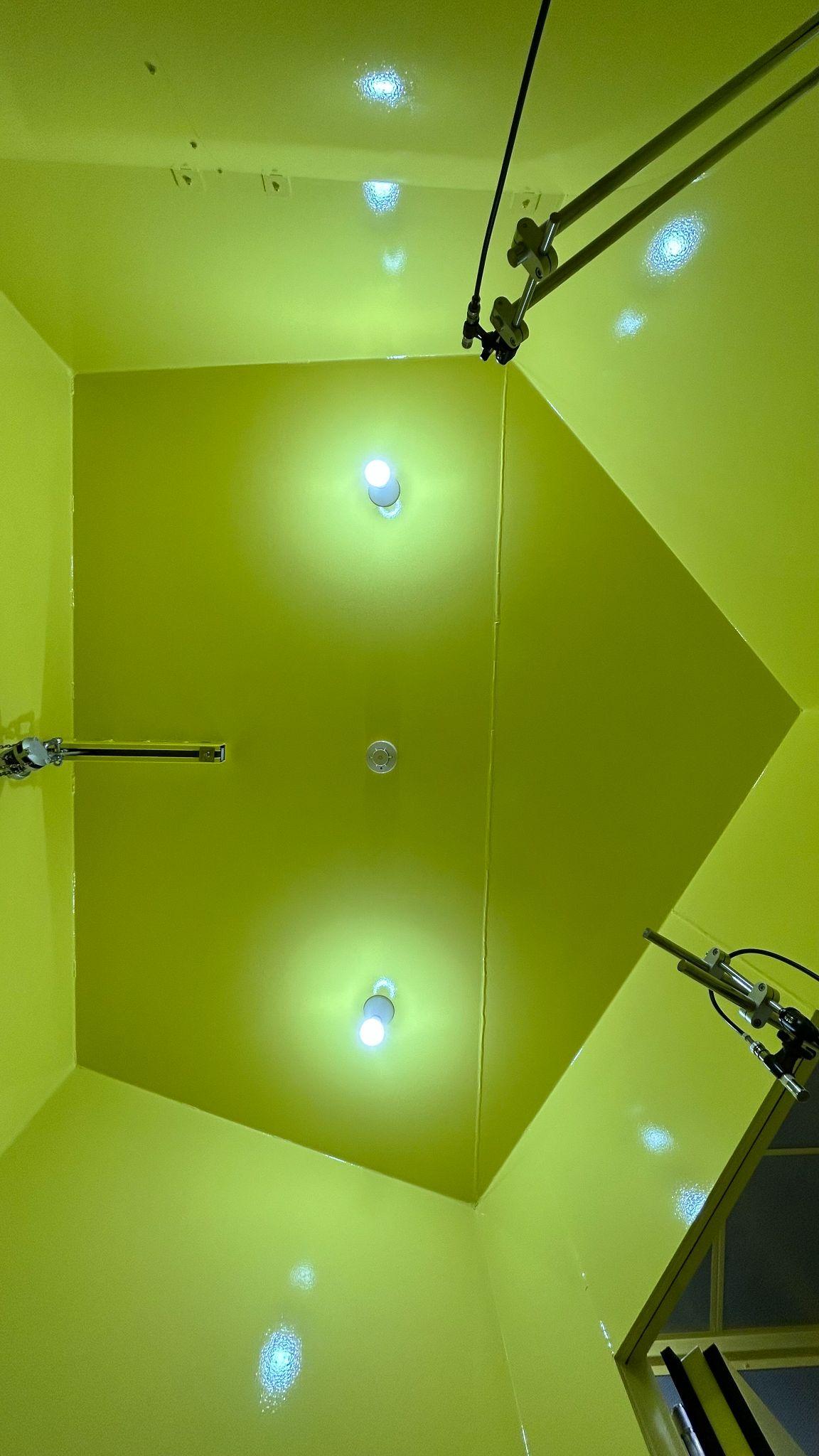

| Optimized Internal Acoustic Characteristics | Specialized surface finishes ensure sufficient reverberation times needed for testing purposes. Sound diffusion can also be enhanced by integrating ribbed structures or diffusers inside the room. |

| ISO Compliance | The rooms are designed to comply with standards such as ISO 3741 and ISO 354, |

Summary of Key Differences

| Item | Traditional Reverberation Room | SONORA Steel Reverberation Room |

|---|---|---|

| Material | Concrete, Masonry | Steel Panel + Damping Structure |

| Weight | Extremely heavy (tens of tons) | Lightweight (1/3 to 1/5 of traditional rooms) |

| Construction | Long build time | Quick installation, relocatable |

| Sound Insulation | Based solely on mass law | Mass law + damping design |

| Acoustic Properties | High reflectivity, rich reverberation | High reflectivity, uniform sound field |

| Cost | High (construction type) | Efficient (panel type) |

| Flexibility | None (fixed structure) | High (modular and relocatable) |

Why SONORA’s Steel Reverberation Rooms Are Chosen

- Short lead time from installation to start of testing

- Highly flexible for future relocation or layout changes

- Designed for easy compliance with ISO standards

- Reduced structural load on existing buildings, offering more site flexibility

Thanks to these advantages, SONORA’s steel reverberation rooms are becoming the standard model for acoustic testing environments in industries such as automotive, home appliances, and construction materials.