Sound absorption materials : Methods to increase absorption rates in the Low frequency range

10/07/2024

MFAC / MSAC

Recently, someone introduced me to a press release article about “low-frequency sound absorption materials for anechoic chambers developed by another company.” Upon seeing the article, I thought, “Not again…”

Development of Low-frequency sound absorption materials

For about the past ten years, particularly around the theme of “enhancing sound absorption rates in the low-frequency range,” the development of sound absorption materials for anechoic chambers has been advancing both domestically and internationally. The catalyst for this was undoubtedly the introduction of F corporation’s sideband sound absorption materials.

Our company has also conducted research on low-frequency sound absorption. Various sound absorption materials have emerged from other domestic companies as well.

As a result, all of these sound absorption materials ended up being quite similar to F corporation’s wideband sound absorption materials.

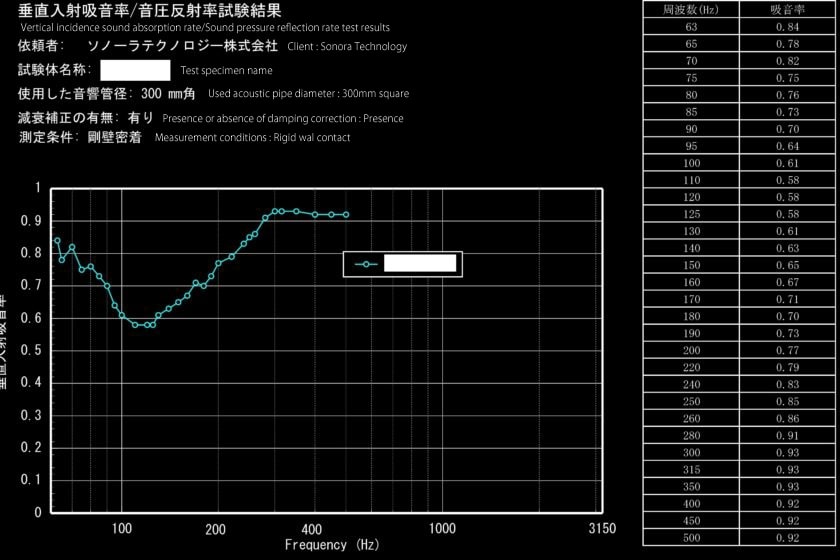

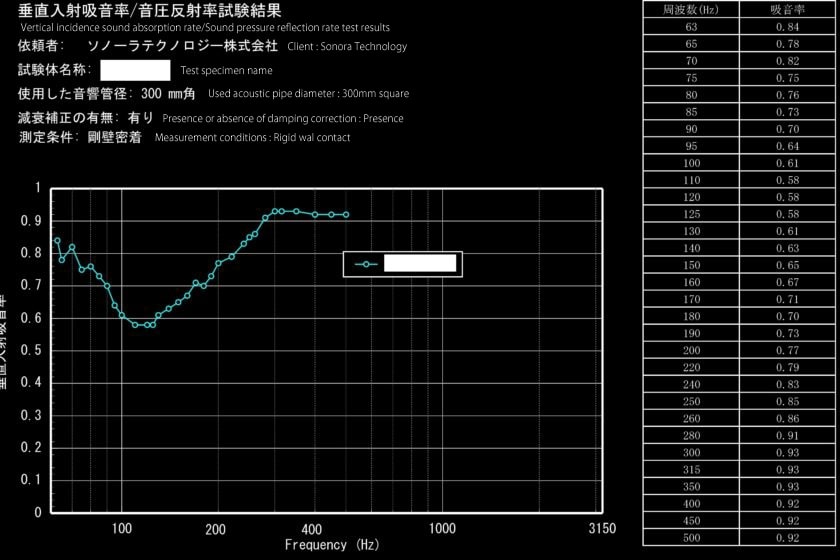

Please take a look at the graph below.

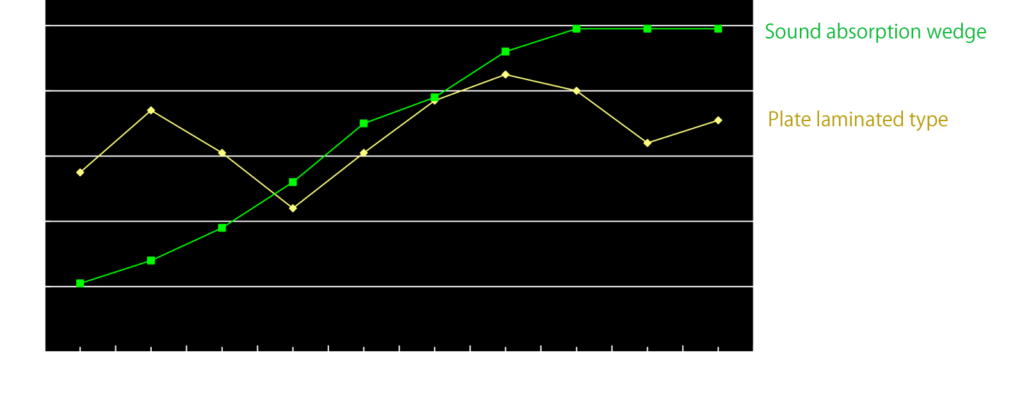

Wideband sound absorption materials are often of the plate laminated type, typically in the form of square blocks.

The typical sound absorption material used in anechoic chambers has a wedge shape.

When comparing the two, the plate shape has a higher sound absorption rate in the low-frequency range, while the wedge shape has a higher sound absorption rate in the high- frequency range.

In other words, the theme of “enhancing sound absorption rates in the low-frequency range” is not inherently difficult; it can be achieved simply by changing the shape of the sound absorption material.

In addition to changing the shape, another method is to incorporate resonant elements (such as resin or membranes) within the sound absorption material.

However, these methods do not address the drop in absorption rates in the high-frequency range, and adding various materials will increase the cost of the sound absorption material. This raises the question of whether that is visible for a product.

Some other companies have released sound absorption materials with reduced high-frequency absorption rates as products. However, since acoustic measurements conducted in anechoic chambers also assess high-frequency sounds, having low absorption rates in this range makes these materials unsuitable for use in anechoic chambers.

Increasing sound absorption rates in the low-frequency range results in a decrease in absorption rates in the high-frequency range.

Increasing sound absorption rates in high-frequency range lead to a decrease in absorption rates in the low-frequency range.

These adjustments can be seen as simply shifting and turning the frequency range with high absorption rates, similar to the resonant frequencies of vibration-damping materials. Therefore, even if a sound absorption material has high absorption rates in the low-frequency range, I believe it cannot be considered superior overal. Increasing absorption rates solely in the low-frequency range is not technically challenging.

How to enhance sound absorption rates across all frequency ranges?

It is possible to enhance sound absorption rates over a wide frequency range, but this often leads to a decrease in the maximum absorption rate. Maintaining high absorption rates across all frequency ranges without changing the volume of the sound absorption material seems to be quite challenging.

The sound absorption rate is relatively high below 100Hz, reaching above 0.9 around 280Hz, but it does not reach 0.985. (This refers to a plate-type sound absorption material that is approximately 350mm thick.) While the absorption rates for frequencies above 500Hz are not specified, they undoubtedly decline.

If you were a developer of sound absorption materials, could you confidently say, “I have developed a new wideband sound absorption material!” Based on this data? While “wideband” sounds appealing, it also implies that the performance across various frequency ranges may be only marginal.

The data from the press release article about the “low-frequency sound absorption materials for anechoic chambers developed by another company” was similar. Moreover, that data was obtained using the reverberation chamber method, so I believe the performance of the sound absorption material mentioned above is even better.

Since anechoic chamber materials are thicker, measuring them using the reverberation chamber method yields exceptionally good data, which is not helpful as a reference.

However, what I have mentioned so far is merely a discussion of “individual points.”

When individual points connect to form lines, and then expand into a surface, the possibility of achieving sound absorption in the frequency ranges that are currently lacking begins to emerge.

The term “point” refers to the fact that these are performances of the sound absorption materials in isolation.

When installing sound absorption materials in an anechoic chamber, it is not just a single material. In a full anechoic chamber, sound absorption materials are applied to all six surfaces: the floor, walls, and ceiling. In a semi-anechoic chamber, they are installed on five surfaces, excluding the floor.

In that case, instead of considering the sound absorption rate of a single unit, we are looking at 300 or even 1,000 units. As the anechoic chamber increases in size, the quantity of sound absorption materials also increases. The arrangement of the materials changes, and the way sound reflects can vary depending on the room’s aspect ratio.

In our previous article (Lab test data = reality?), we stated the following

-> The sound absorption rate data is based on measurements from lab tests and should only be considered as a reference. Conversely, it is possible that a sound absorption material that performed exceptionally well in lab tests might not exhibit significant sound absorption when applied throughout an entire room.

∴Therefore, sound absorption design requires a three-dimensional approach.

For these reasons, our company bases its standards on the overall performance of the entire anechoic chamber rather than the numerical values of sound absorption rates for individual sound absorption materials.

This applies not only to anechoic chambers but also to concert halls. The acoustic design of the concert hall is a three-dimensional design.