Needless to say, no need for anechoic chambers to be surrounded by the rear-side air layer!

07/04/2024

MFAC

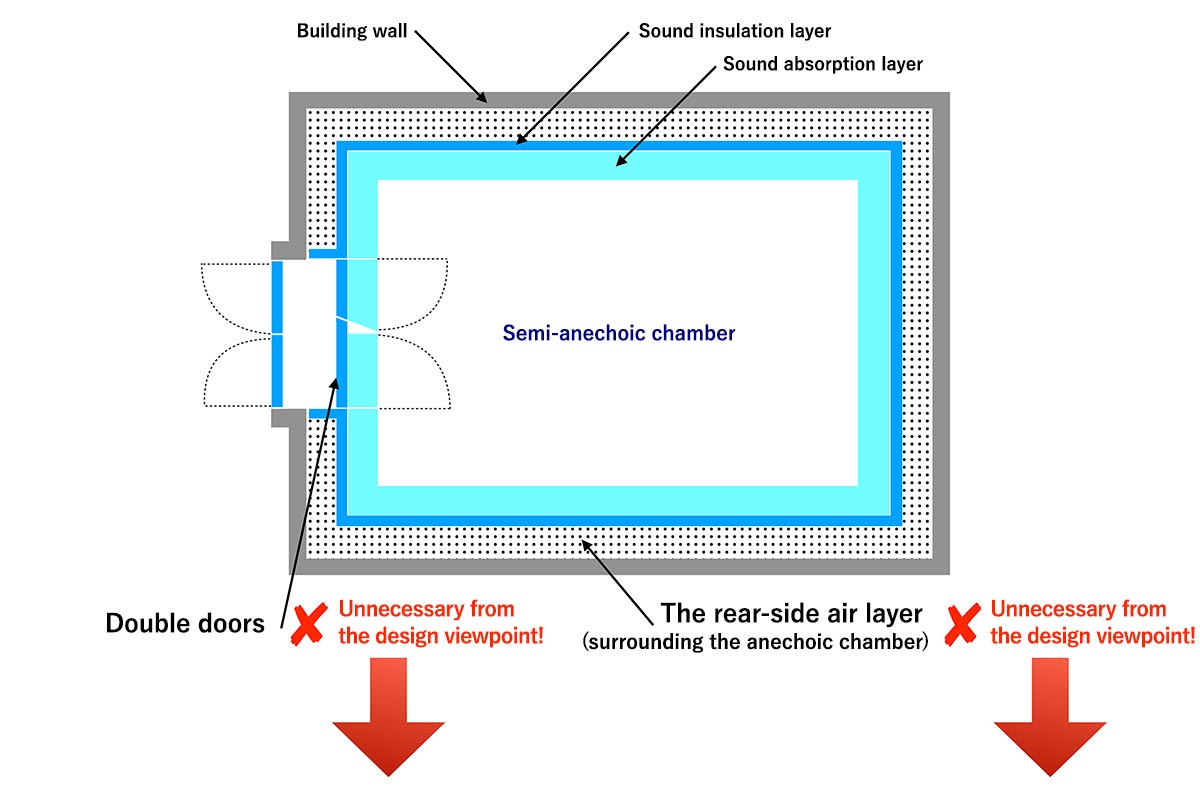

In general, the conventional construction methods for an anechoic chamber involve installing a “rear-side sound absorption layer” behind the sound insulation layer of the anechoic chamber.

The reason why is that the conventional construction methods result in creating the weak sound insulation layer, which making difficult to realize sound insulation in the low frequency range.

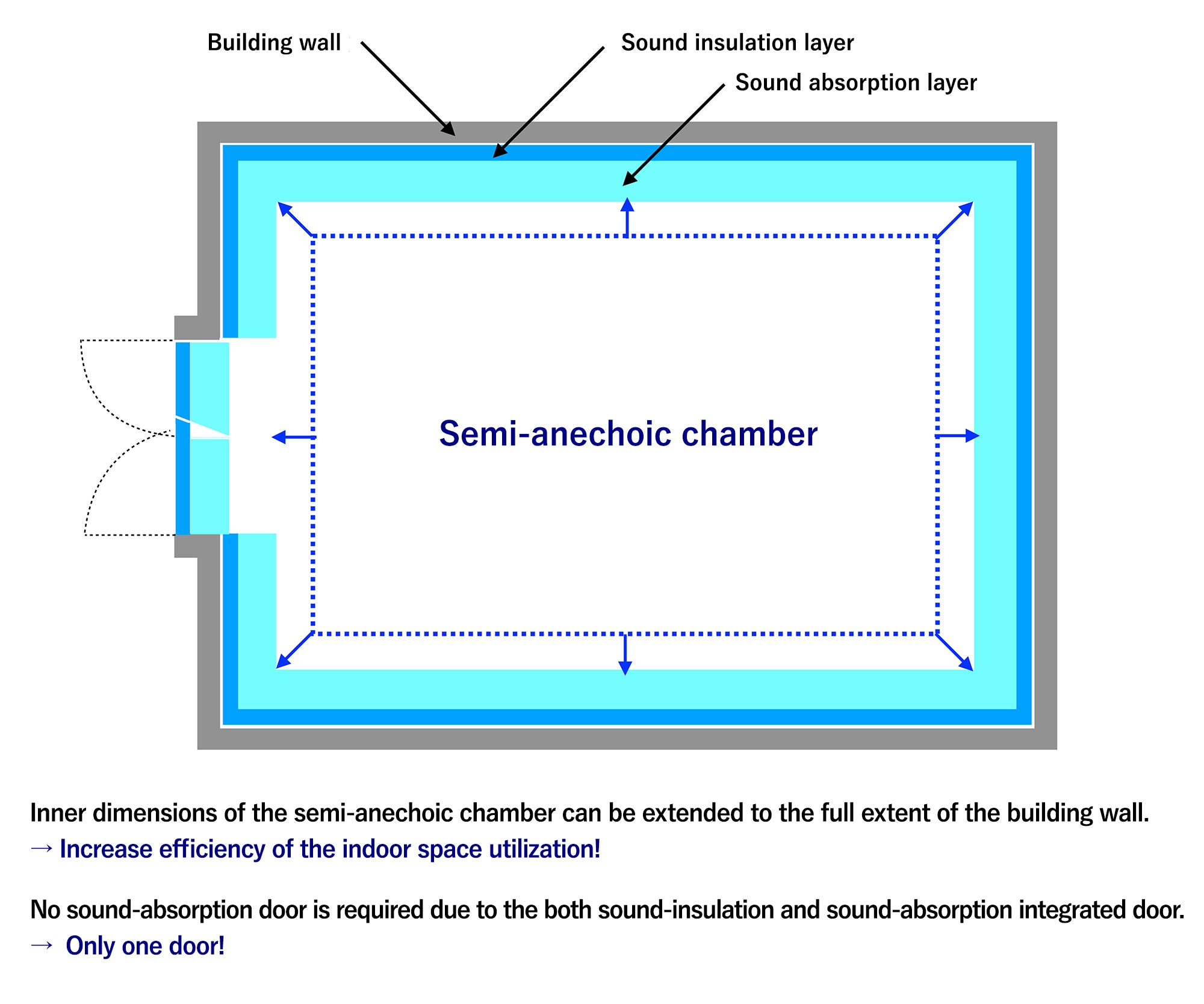

Sonora’s made-of-steel sound insulation panel are designed to be incorporated in the sound insulation layer.

As the steel sound insulation panels itself can perform solely the required sound insulation for the anechoic chamber, there is no need to secure such a large “rear-side air layer.”

It should be pointless, no need of the rear-side air layer.

In conventional construction methods, around 1m-width space only for a rear-side air layer may be designed depending on project cases.

*Sonora calls the rear-side air layer as the “running space”, which means a useless, meaningless space to allow us running for training around the anechoic chamber.

In addition, as described in the above-mentioned diagram, only one single door is sufficient according to Sonora’s design of the anechoic chamber.

No one get benefits from over-designing!