Acoustic Measurement in Environments Using Water

09/18/2024

MFAC / MSAC

When measuring the sound of water-using products such as water heaters in an anechoic chamber, the acoustic materials (sound-absorbing wedges) can absorb water.

When these materials absorb water, the air bubbles, which are the entry points for sound, become clogged, significantly impairing their sound-absorbing performance.

Additionally, water that has entered the acoustic materials is difficult to remove, which can lead to deformation of the materials and cause mold growth.

So, how is acoustic measurement conducted in environments where water is used?

- (1) Use sound-absorbing materials with water permeability, and set up a waterproof tray or similar to collect the water and allow it to drain outside.

- (2) Use water-resistant sound-absorbing materials

These measures are common, but there are some issues.

First, with (1), while it is possible to drain the accumulated water, the sound-absorbing

materials intermittently become clogged until water is fully drained.

(2) For water-resistant sound-absorbing materials, some commercially available options may have their water-resistant properties degrade over time due to aging and other factors such as water-repellent sprays or coatings.

So, what should be done?

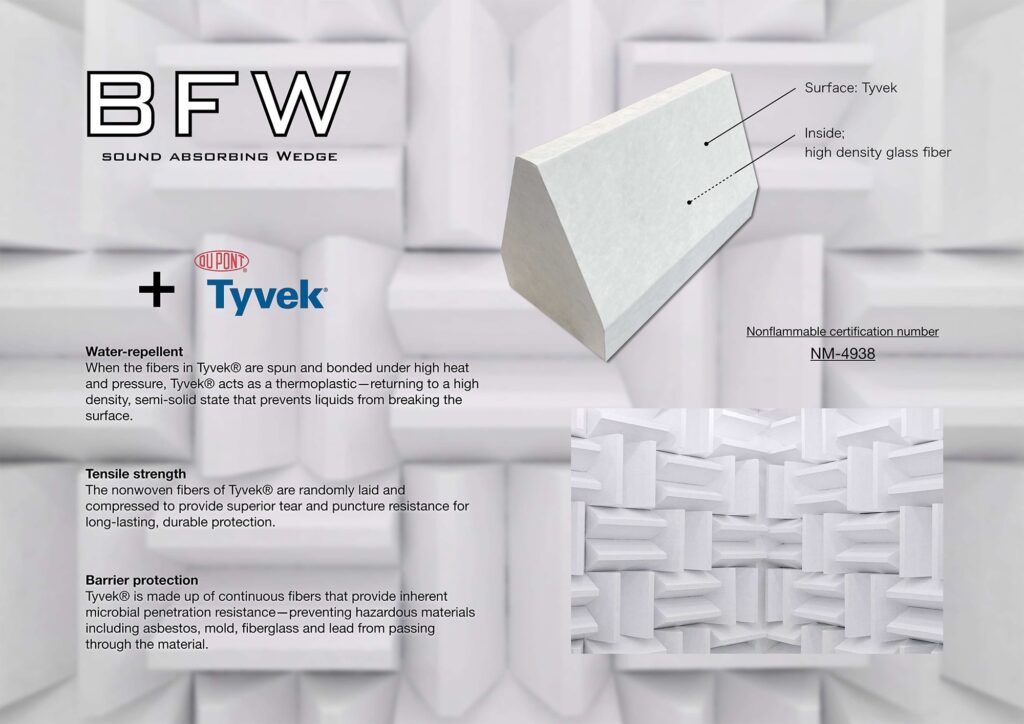

This may sound like a promotion, but the solution is to use our company’s original sound-absorption wedges, BFW for interior finishing.

BFW uses a fabric called Tyvek, which is water-resistant and water-repellent. This prevents water from penetrating into the sound-absorbing material when it comes into contact with the surface.

Sonora Technology has a semi-anechoic showroom featuring the BFW specifications, where you can see the actual product.