Issues on anechoic chambers manufactured by other manufacturers -1

07/24/2024

MFAC

An anechoic chamber was supplied by a German anechoic-chamber manufacturer to a Chinese automobile development company P. According to the request by the company P, Sonora Technology was asked to conduct acoustic measurements.

* the reason why: the company P had doubts about the sound absorption performance of the German-made anechoic chamber.

Sonora conducted a measurement of inverse square law on site.

As a result of that, we found that the sound absorption performance in the high-frequency range had decreased.

Sonora reported the measurement results and issues to the company P.

As the high-frequency band is included in the scope of measurement by the company P, it means that the anechoic chamber does not fulfill the conditions of use or delivery of the anechoic chamber.

This anechoic chamber has had other issues as well.

This German-made anechoic chamber had a flat laminated sound-absorbing layer, with an exposed melamine foam for finishing.

Melamine foam has a high sound absorption performance by itself, and we do not deny the use of melamine foam as a sound absorbing layer in an anechoic chamber, but it has some disadvantages depending on the way it is used.

Issues

A. Melamine foam has less durability and is easy to crack by just a little press with a finger.

Firstly, the areas where people touched by hands in this anechoic chamber were fragile and tattered. Only when pressed with a finger, the foam cracks and cannot return to its original shape. The sound-absorbing layer is quickly tattered out when workers or visitors touch it. This not only looks bad, but also has poor sound absorption performance compared to when it is new.

B. Melamine foam is sensitive to heat.

Melamine foam has a heat-resistance temperature of about 240°C and a safe-operating temperature of about 150°C. In other words, it will burn in the vicinity of heating elements.

The melamine foam is generally not used in anechoic chambers for acoustic measurements of automobiles and automobile parts, as it may be affected by engine heat and exhaust heat as such. It is also not allowed under the Japanese Building Standards Act. Materials used inside anechoic chambers must have a non-combustibility certificate approved by the Ministry of Land, Infrastructure, Transport and Tourism.

* This is one of the reasons why overseas anechoic-chamber manufacturers cannot enter the Japanese market.

C. Melamine foam is easily soiled and clogged.

Melamine foam is used in Japan as a kitchen stain-removing sponge called “Gekiochi-kun.” The microscopic fine air bubbles in melamine foam make it easy to remove dirt.

On the contrary, it is also easy to get dirty. Since the sound absorber is a material that allows sound to absorb along with the air, when the dirt gets on the surface, it can cause clogging and significantly reduce the sound absorption performance.

D. The flat laminated sound-absorbing layers have lower sound absorption performance in the high-frequency band compared to the wedge-shaped sound-absorbing layers.

Anechoic chambers are generally designed with wedge-shaped sound-absorbing wedges. However, this one is flat-plate finishing, which has slightly better sound absorption performance in the low to mid frequency range compared to the wedge-shaped one, while tends to drop off in the high frequency range.

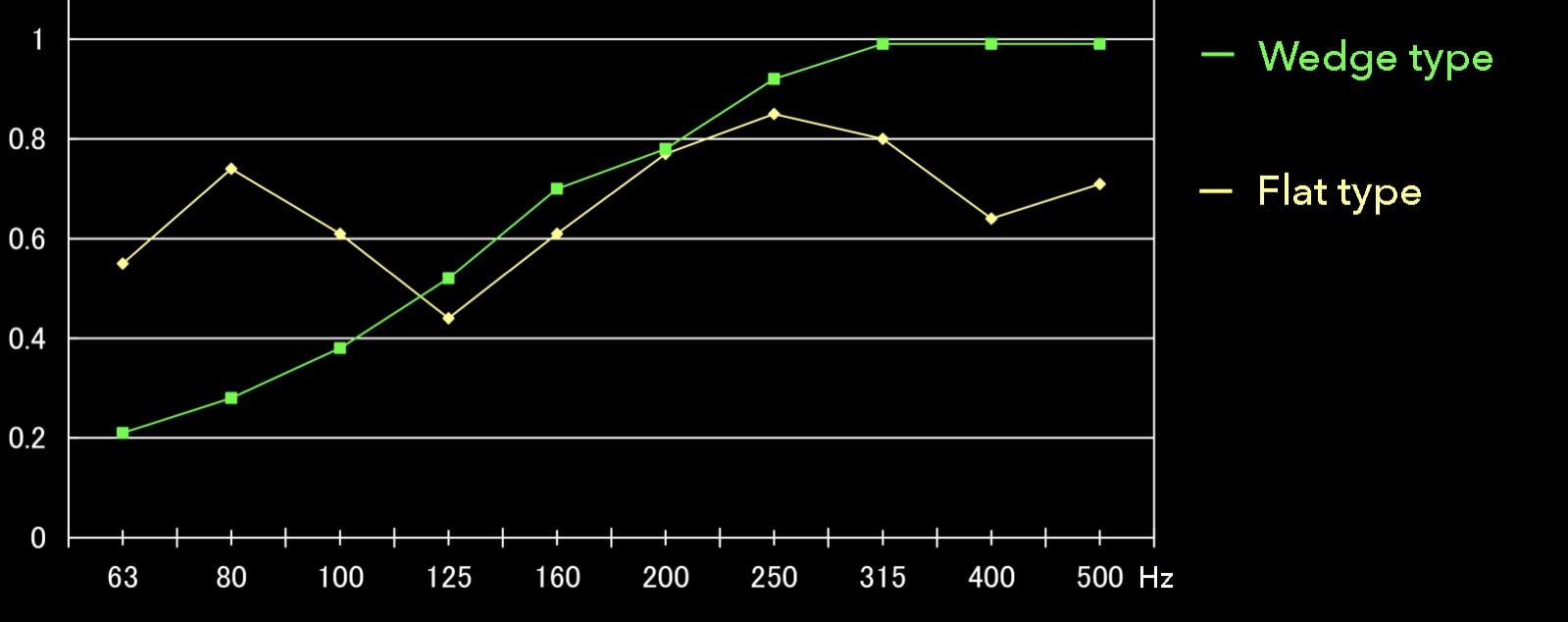

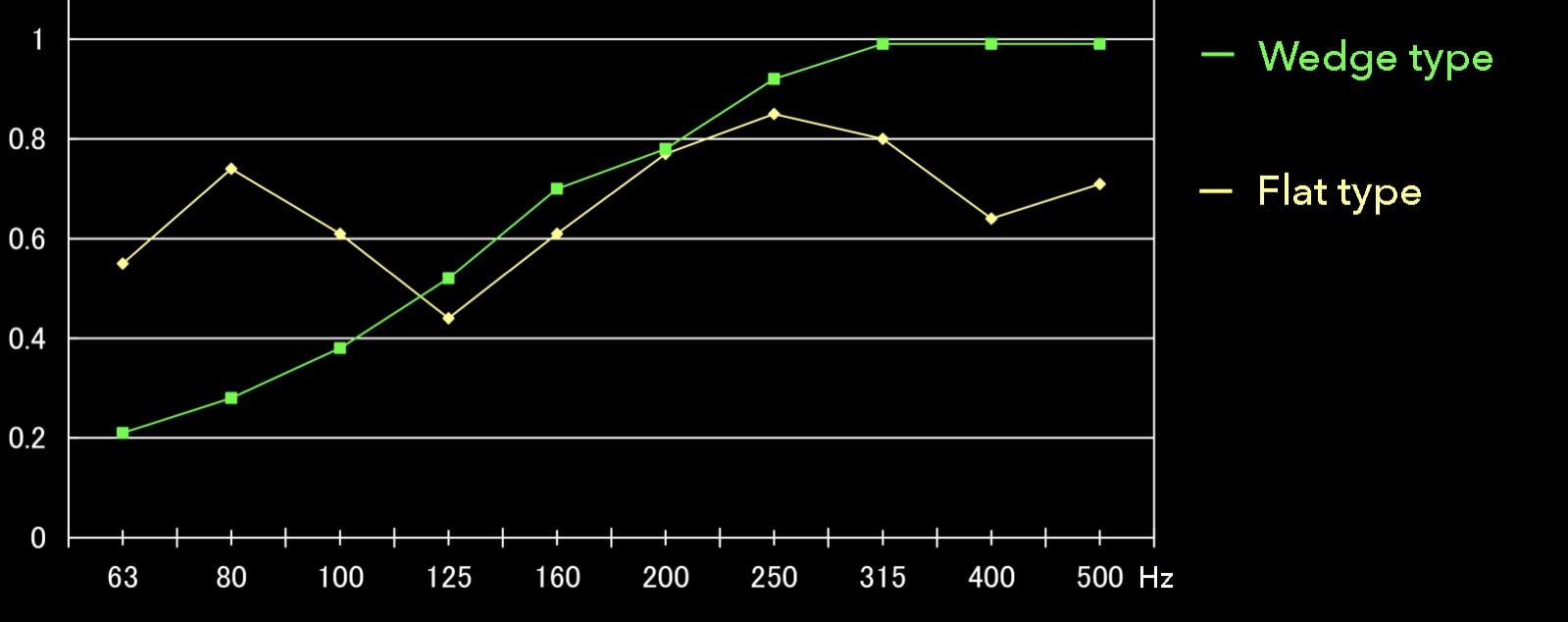

Below is a comparison of the vertical incident sound absorption coefficient between a flat-laminate type and a sound-absorbing wedge type.

The data of vertical incident sound absorption coefficient: a comparison between the same materials with the same thickness

Thus, there is a significant difference between the flat laminate type and the sound-absorbing wedge type. The flat laminate type has a higher sound absorption coefficient than the sound-absorbing wedge in certain frequency bands, while it is very unstable.

In particular, the sound absorption coefficient does not reach at one (1) in the high-frequency range, where the wavelengths should be shorter and the sound absorption easier.

Companies proposing flat-plate type anechoic chambers to customers, like this one, often say a kind of cliché, like the following:

- Excellent sound absorption performance in the low frequency range, better than that of wedges

- There is a drop in the high frequency range, however, no problem as long as the thickness of the sound-absorbing layer is within λ/4 of the frequency.

But you know the results?

It’s true that there are certain users being annoyed by the high-frequency echoes.

So why has the delivery of anechoic chambers already been completed?

This is because such manufacturers conducted their own measurement of inverse square law and reported them as the performance data upon completion of delivery. In addition, there were no performance guarantees by manufacturers, and the actual measurement values were not verified by users themselves.

As you can see, there are many anechoic-chamber manufacturers who cheat you out or just focus solely on making sales without any after-sales service. So, please be careful with such issues.

And ask anechoic-chamber manufacturers thoroughly to guarantee the performance of their products.

There are excellent anechoic-chamber manufacturers in the world, while not-so-good ones as well. So, we’d like to compete with excellent nominees.

- Excellent proven anechoic-chamber manufacturers

- Company F in Krumbach, GERMANY

- Company I in Hampshire, UK

- Company E in Massachusetts, USA

AND

- Sonora Technology Co., Ltd. in Tokyo, JAPAN