New sound absorbing material BF series

At Sonora, we are constantly developing sound absorbing materials. We would like to introduce the BF series, t...

Our new panel achieves “ultra-thin and high performance” even with “lower cost”

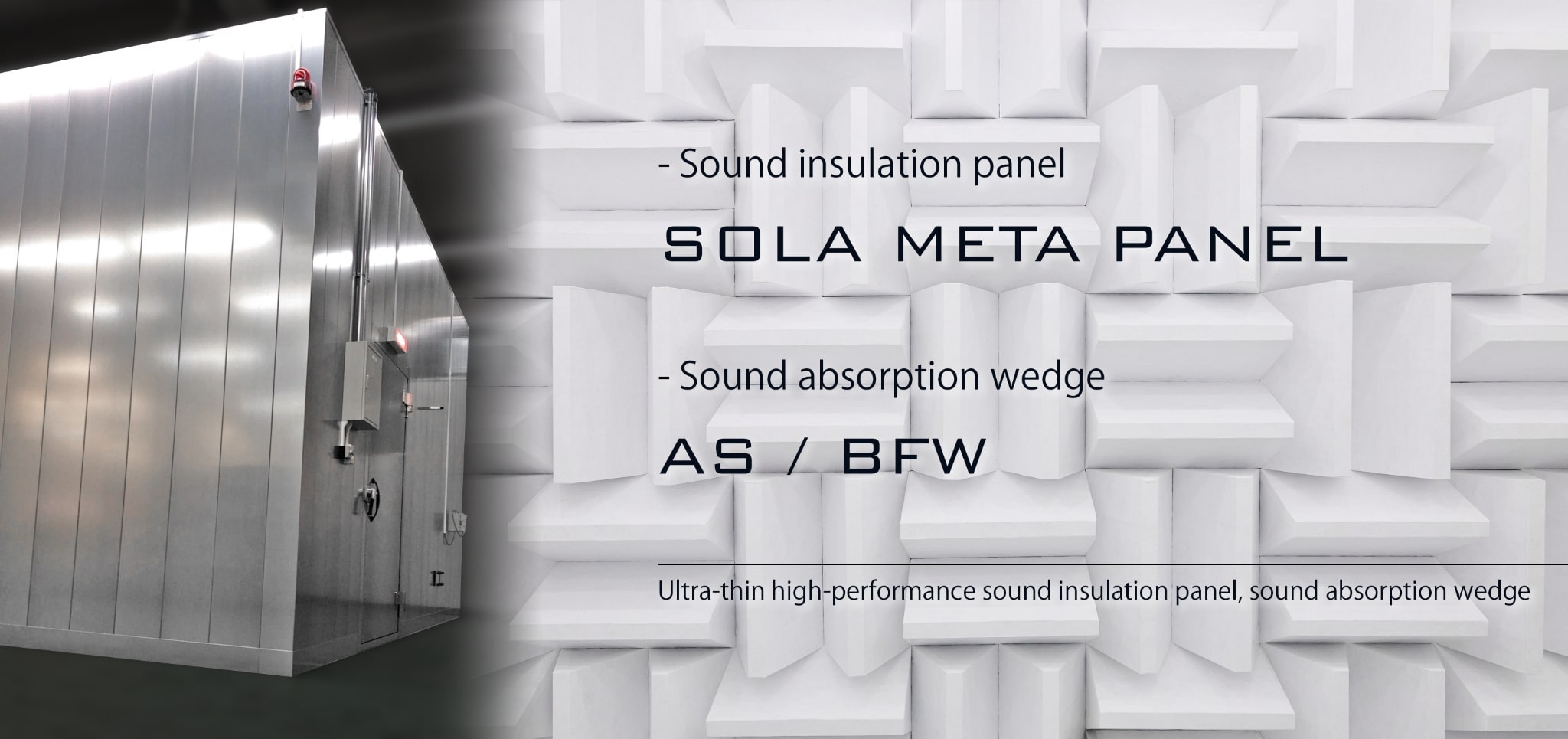

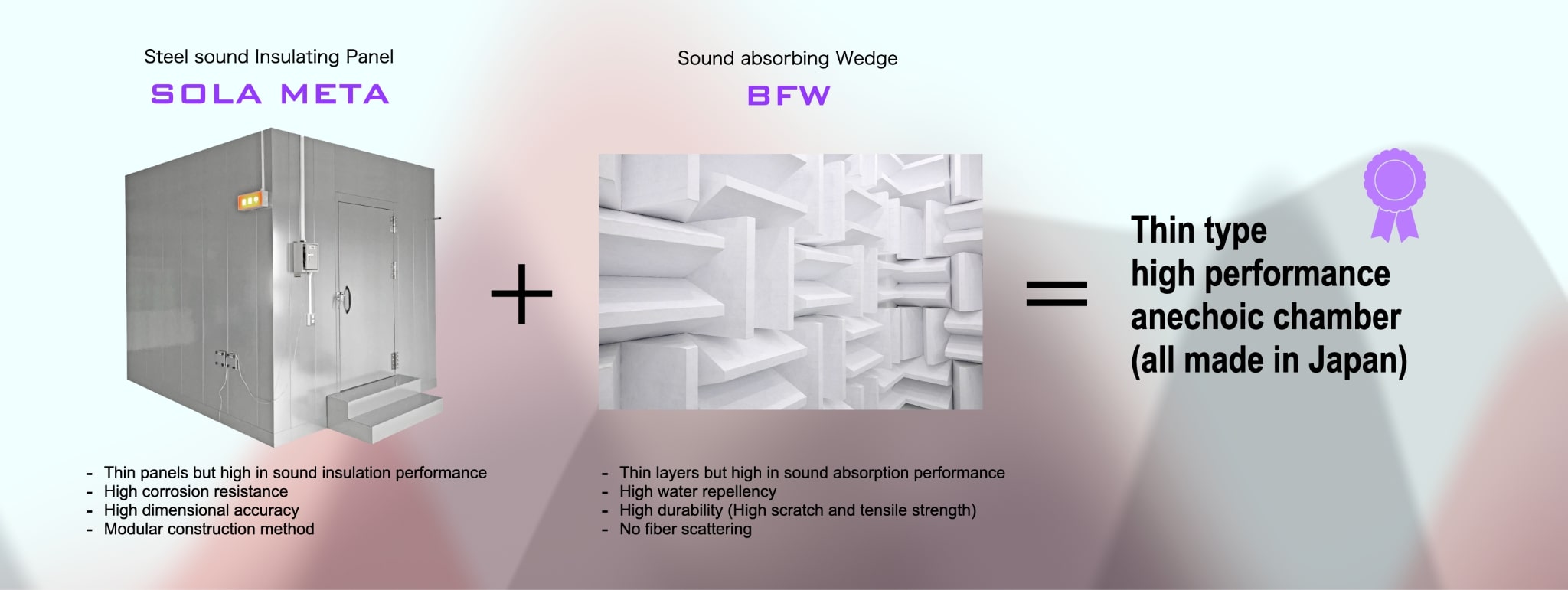

The “New Sound Insulation Panel” and “New Sound Absorption Wedge” originally developed by Sonora Technology Co., Ltd, a sound-proof and anechoic chamber manufacturer, are innovative technologies that achieve “ultra-thin and high performance” even with “lower cost”. These will make significant changes in the future design of sound-proof and anechoic chambers.

The “SOLA META Panel 3TS series”, a thin sound insulation panel, was developed by combining three elements: sound insulation, sound absorption and vibration control.

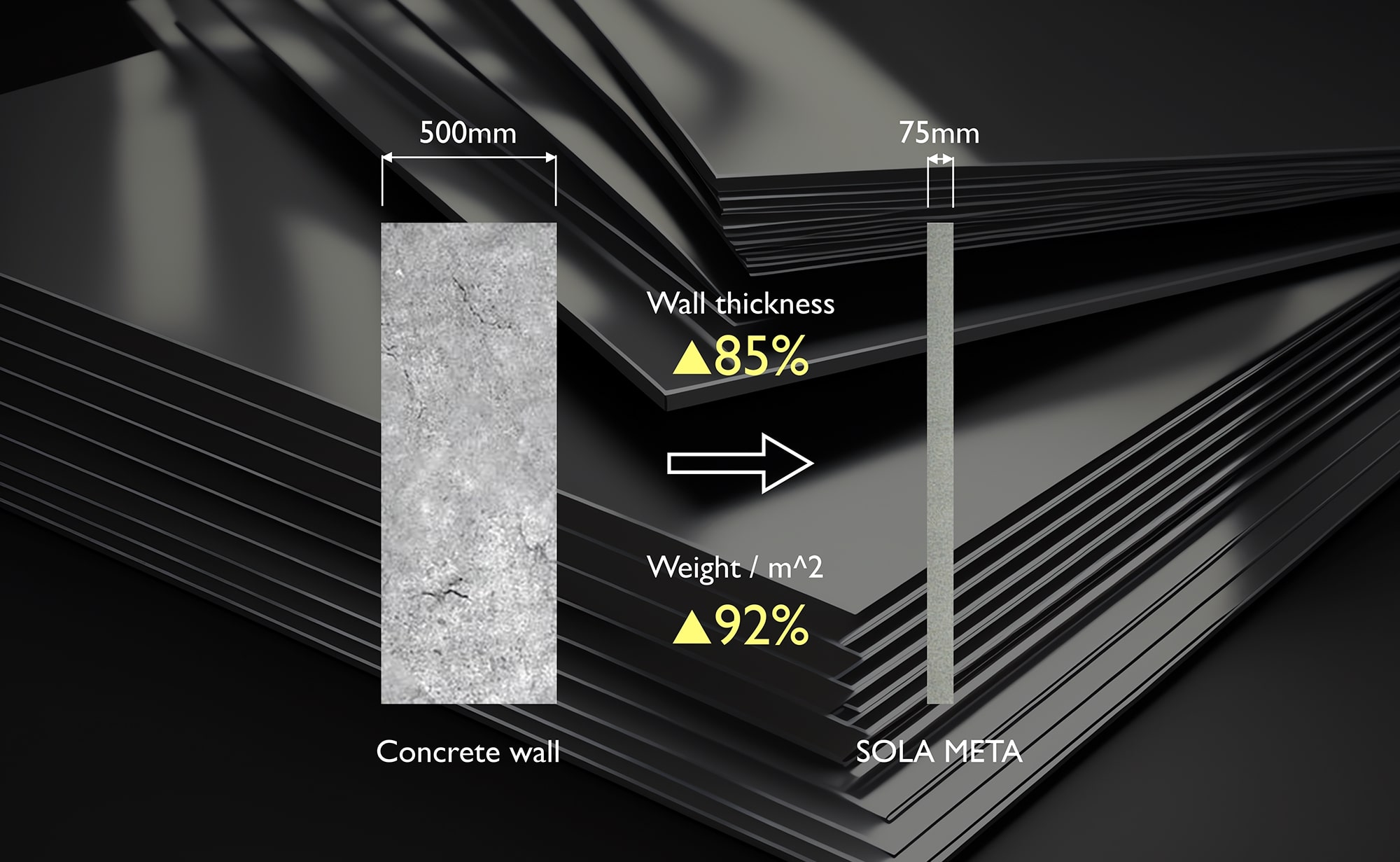

The sound insulation performance of SOLA META Panel (3TS-75) is equivalent to a concrete thickness of 500 mm at a panel thickness of only 75 mm.

It is also far lighter than concrete, which means that it is approximately 92% lighter than a concrete thickness of 500 mm.

| Components Total thickness of 75mm | ・External walls: high corrosion-resistant steel plate ・Zinc-galvanized steel plate ・Vibration-reducing stiffener ・Resin-type vibration isolation material ・Resin-type adhesive layer ・High-density sound absorption panel ・Resonance plate (also used for high-frequency sound insulation) ・Inner bolt for torque setting |

The “new sound insulation panel 3TS-75” reduces wall thickness by 85% and m^2 weight by 92% when compared to a concrete thickness of 500 mm.

Sound insulation level in the medium to high frequency range has been increased to the limit.

Sandwich effect due to the rigidity of steel and the multi-layer structure of plate.

Sound absorption in the medium to high frequency range using high-density sound-absorbing material.

Achieves low-frequency sound absorption by resonance.

Vibration is controlled by vibration isolation material, adhesive layer, stiffener, and inner bolt.

We have combined these three elements in order to create a lightweight, high-performance sound insulation panel.

* As we will not be patenting them, we cannot reveal the details.

Ensuring high performance from low to high frequencies is a challenge due to negative aspects in the design of each element (especially resonance and sound insulation deficiencies at certain frequencies). We have achieved it by assisting and adjusting by structural materials and through the repeated test measurements.

Regarding the sound insulation performance values, please refer to the sound insulation values of our products equipped with SOLAMETA Panel 3TS. The sound insulation performance varies depending on the sound-absorbing layer of the inner wall.

The highly corrosion-resistant steel plate used for the outer wall material is a specially-plated steel plate containing zinc + magnesium + aluminum. This is 10 times more resistant to corrosion than hot-dip galvanized steel plate. It is also resistant to rust and has proven experiences in outdoor use.

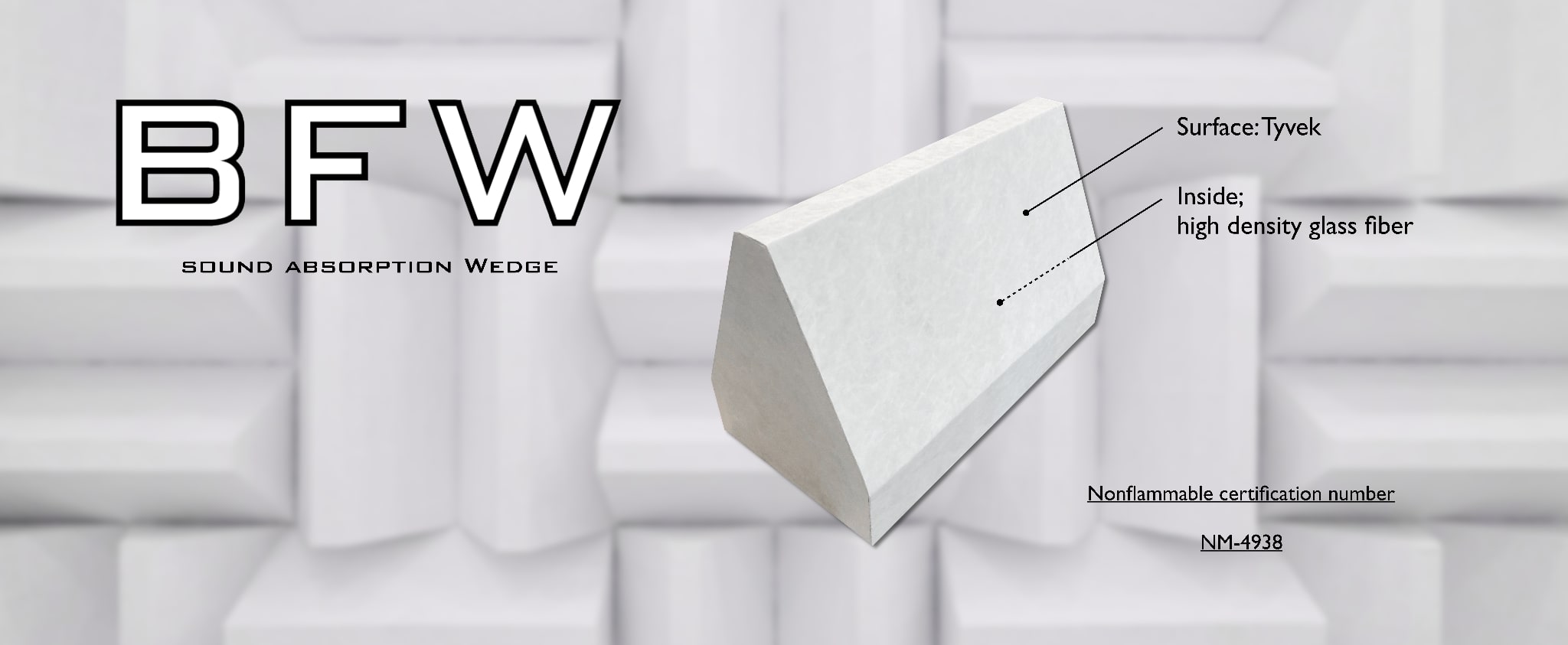

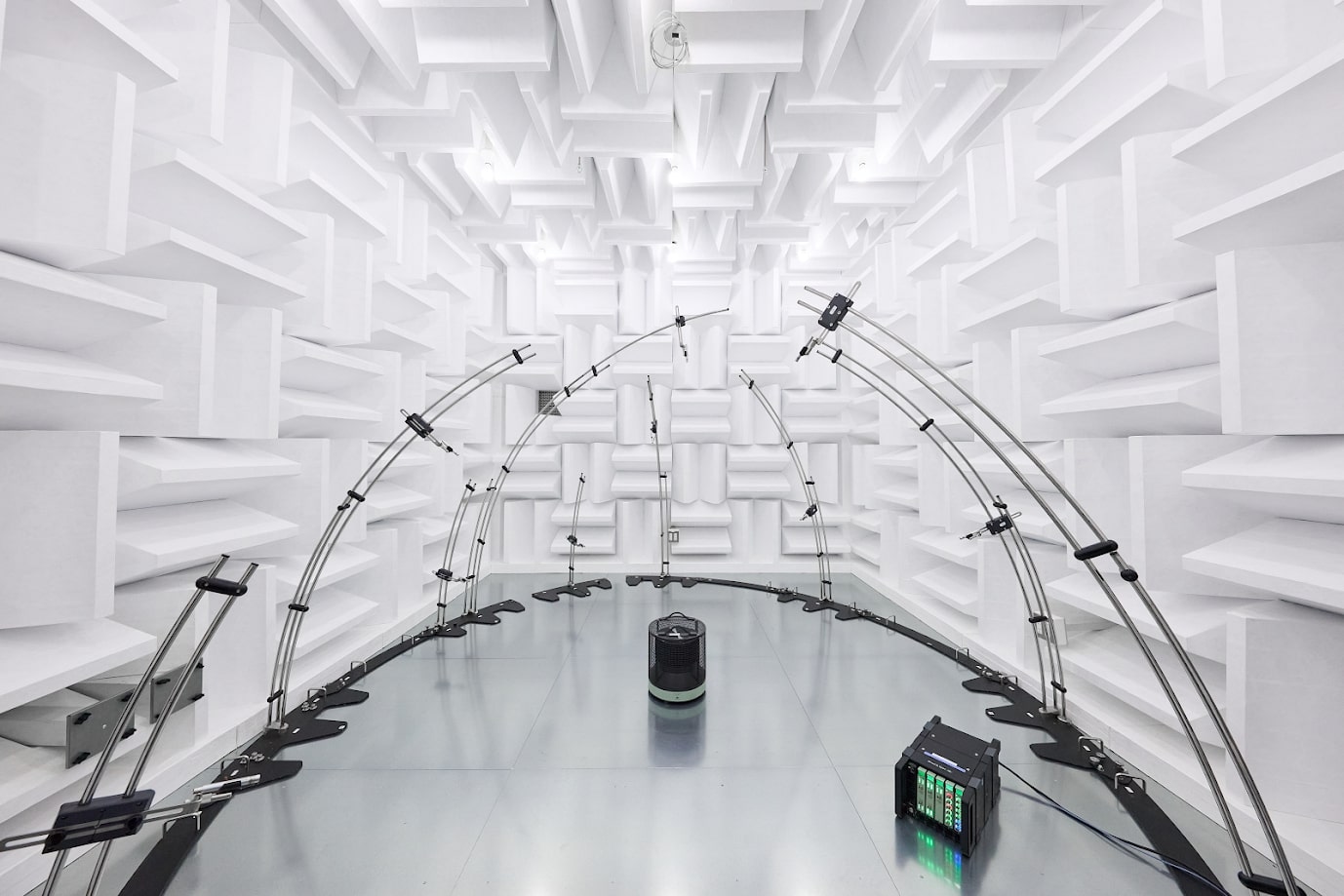

Our new sound absorption wedge ”BFW” (standard product: “AS”) is a multi-functional sound absorption wedge.

High-density sound absorber + Tybek provides the following functions:

| High water-repellent and water-resistant | Tybek is water and dust-resistant. Can be used in a variety of environments. |

| Scattering-free fiber | Prevents fiber scattering of sound absorbers. |

| Tensile strength | Tensile and scratch-resistant, with higher strength than conventional glass cloth and non-woven fabrics. |

| High whiteness and high design quality | Tybek is highly opaque, having excellent design properties not to affect the color of the back material. It also eases to ensure sufficient illumination. |

Unlike conventional sound absorption wedges used in anechoic chambers, BFW is

not only absorbing sound, but also having a function of acoustic attenuation due to its internal structure, resulting in a high sound absorption rate despite its compact size. It is 40% less compact than conventional sound absorption wedges.

BFW is a sound absorber, while BFW itself also has sound insulation properties, reinforcing the sound insulation performance of the anechoic chamber.

Sound absorbers (and its density) suitable for each of the low, mid and high frequency ranges are selected and are combined to make sound absorption wedges. By selecting several materials for the surface, we have developed the sound absorption wedges as thin as possible.

Diaphragm is incorporated inside the wedge to absorb low-frequency sound, ensuring the sound insulation and low-frequency sound absorption. (model no. AS: V02W)

In addition, a non-frame method is used in order to reduce unnecessary reflective surfaces.

Considering the optimum taper angle, number of ridges, the optimum balance between taper and base, and also based on the theory of surface resistance, our in-house research and development has realized its shape design.

The details of the theory of optimum shape cannot be disclosed, however, please feel free to let us know if you’d like to have a copy of a brochure.

The combination of the new sound insulation panel “Sola Meta Panel” and the new sound absorption wedge “BFW” brings various advantages.